Wiegand Gateway Installation

In order to avoid any confusion or misinterpretation the following document has been drawn up. The primary objective of the dIn order to avoid any confusion or misinterpretation the following document has been drawn up. The primary objective of the document is to establish standards that all installations comply with.

Standards allow for quicker installation time and faster fast turnaround on fault finding. OneSpace will sign off all completed installations based on the standards listed on this page.

Standard Installation Practice

The following are installation best practices that need to be followed.

All devices are mounted at right angles using a spirit level

All installed cables must be labelled at both sides of the cable

All data cable connections must have 0.5mm white ferrule crimped connectors when connecting to the Wiegand gateway connectors

RS485 – Mylar 4pair twisted – maximum total length of 500m

Connect the RS485 cable to the downstream devices using the daisy chain method.

Label the RS485 cable on each device with “From device” and “To” device.

Wiegand – If required connect the Wiegand device, such as keypad reader, cable to the connector block as follows

Red – 12Vdc

Black – GND

D0 - Green

D1 – White

Red LED – Brown

Green LED – Blue

Buzzer – Yellow

Wiegand Output power rating – 200ma

RS485 – Cable Type/Colour Code – A – Yellow / B – Green

Relay – Connection

Connect the output of the relay connectors to the boom gate trigger box with the white rip cord cable. If connecting the relay to a Mag Lock use an external relay timer board to drive the Mag Lock.

Note: Maximum Wiegand cable length is 20m.

Cable Run

The cable run is an important part of the installation. To ensure long term stability of the location it is imperative that the integrity of the cable is a primary focus during installation.

In particular, the following should be considered.

As far as possible the cable should be protected against direct contact with UV from the sun.

The cable should have no friction points on its complete run. The cable should not be run over or near any physical feature that moves or is possibly prone to moving to avoid friction points over time.

If there is a concern or questions relating to the integrity or location of the cable it must be re-run. The cost of a call out later far exceeds the cost of the re-run.

Wiring Requirements

Only specified cable or a direct replacement from an alternative vendor must be used

All cable ends must have the following:

Ferrules

Cable markers as per the assigned number for that cable

All unused cable must be cut away

Where multiple cable cores are used for a single connection, the cables must be twisted together with a ferrule connecting both at the end.

Hardware & Board Description

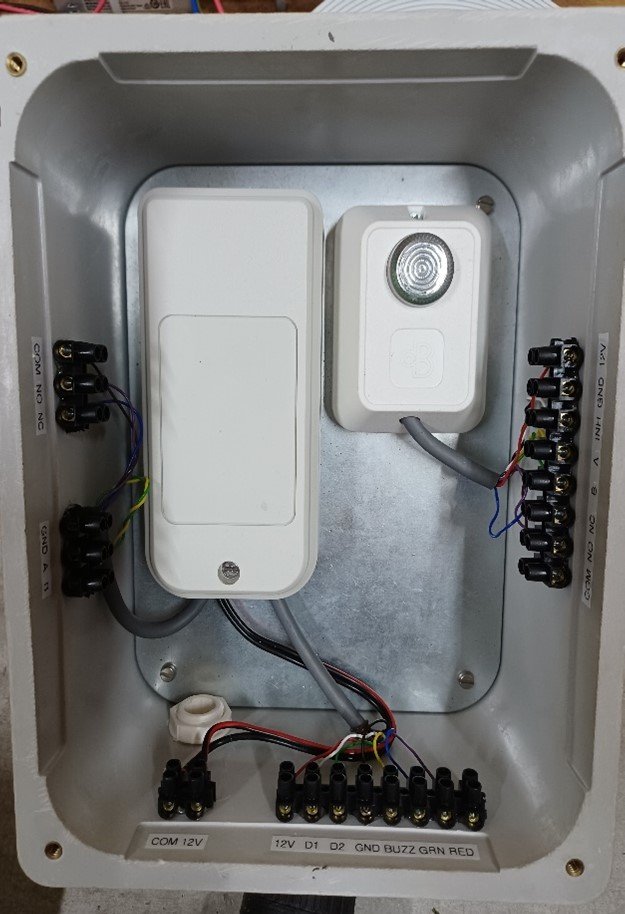

Housing

Hardware

IP65 Case with Wiegand Gateway module fitted – 93xxxxxx

12Vdc Power Supply plus Ground Loop preventor

Cable – RS485 - Mylar 2 pair twisted

Wiegand - Mylar 4 pair twisted

Power – Red/Black rip cord

Relay – white rip cord – boom gate trigger

Ferrules – 0.5mm white

Connector - Block

Cable Colour Code

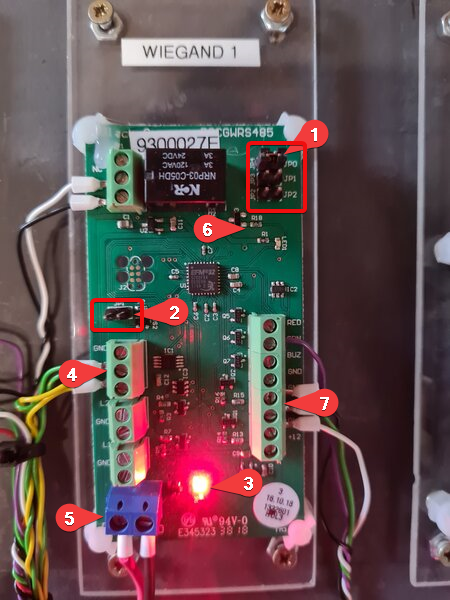

WGND Gateway

Board

RS485 Jumper Slots.

RS485 Termination Jumper Slots.

Power Light.

RS485 Ports.

12V DC Port.

WGND RS485 Polling light.

WGND IN Ports

Installation

Location

Near gate control box or Gooseneck on a suitable stable surface

Mounting

Open the IP 65 case and remove the component panel.

If not already done drill 4 x 6mm holes at each corner of the casing for the mounting screws.

Fasten the casing to the surface with suitable screws.

Re fit the component panel

Power – Connect the 12Vdc supply to the connector block from either the gate motor 12Vdc or a suitable independent 2 amp power pack

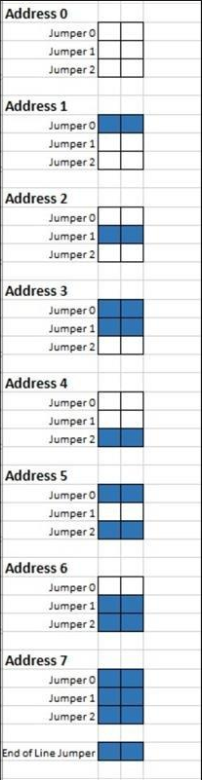

RS485 Configuration

Jumper settings

There can be a Maximum of 8 x RS485 device settings

The Wiegand gateway has a bank of 3 x jumpers to set its RS485 device ID

Each Wiegand Gateway on a RS485 bus has its own unique ID / Address, see image to the right for reference.

Note : If there is only 2 x Wiegand gateways on the RS485 bus then they must be configured as device ID / Address 0 and 1. Similarly if there are 4 Wiegand gateways then they must be configured as device ID/ Address 0 to 3. If one of them is configured higher than 3 then the controller will not pole that device.

As always the last device at the end of the RS485 bus must have a termination jumper installed. This is a single jumper on the PCB

List of configurable RS485 Addresses

Tools Required & Start Up

Tools Required

Ladder

Headlamp

Brother label machine or similar

Extension cord

Drill

Masonry drill and bits

6mm masonry

4mm all purpose drill bits

Flat and Phillips screw driver

Terminal screw driver (<2mm flat blade)

Wire strippers

Ferrules & crimper

Heat shrink (6mm, 4mm & 2mm)

4 x 12mm nut and bolts

6mm masonry wall screw

24mm & 26mm sockets or spanners (for the IP66 glands)

Pencil & tape measure

Laptop with the BeSecure Login

GSM internet connection for the laptop

Start Up

Switch on the 12V power to the Wiegand gateway

Measure the 12Vdc Power supply – If not within a 5% margin then replace

LED Status

The 12V Power LED is next to the connector block and remains on

The on board status LED will flash when the RS485 pole is in service